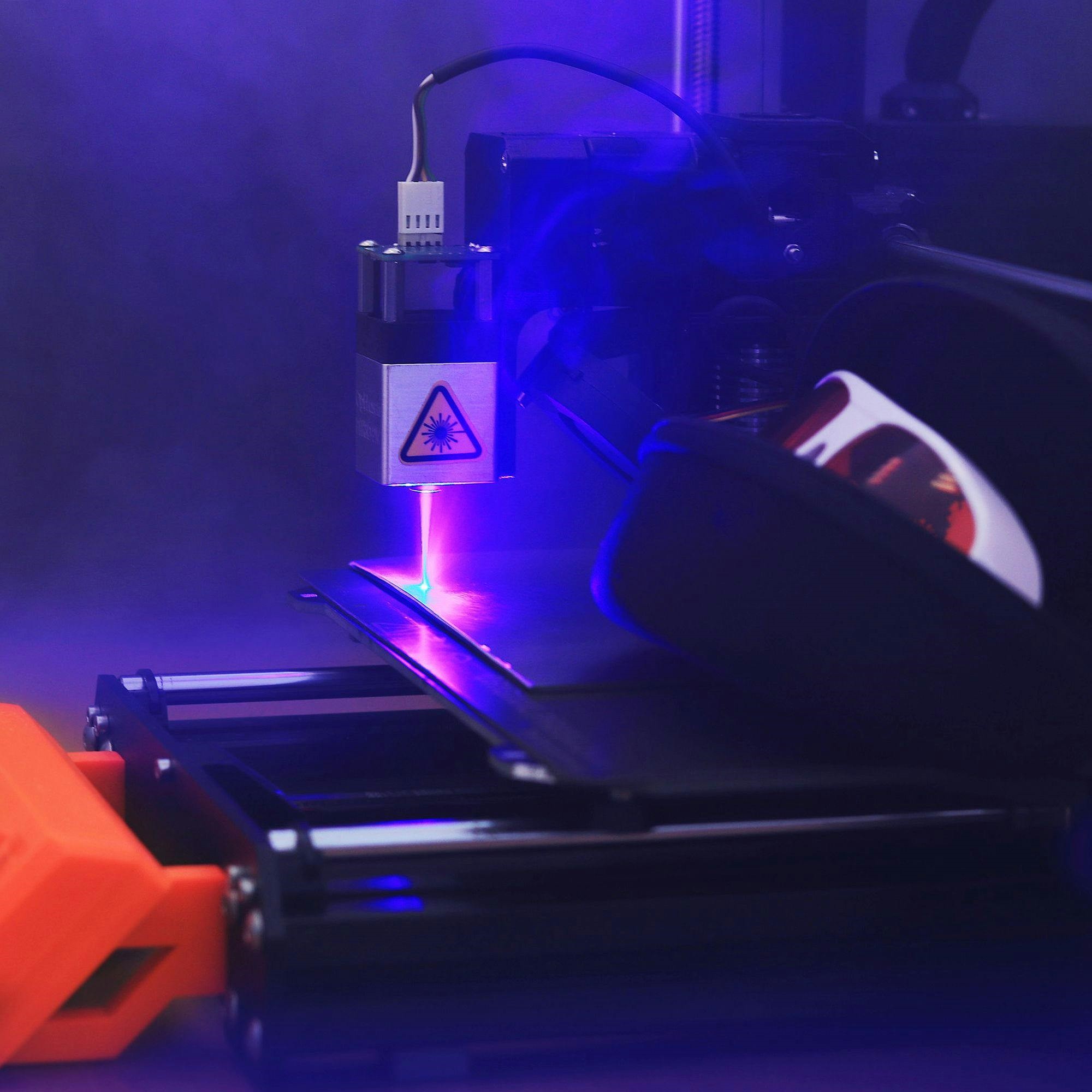

Laser Cutting

Laser cutting offers precise, clean cuts, enhancing your product's manufacturing with intricate designs, efficient production, and versatile material applications.

Laser cutting offers precise, clean cuts, enhancing your product's manufacturing with intricate designs, efficient production, and versatile material applications.

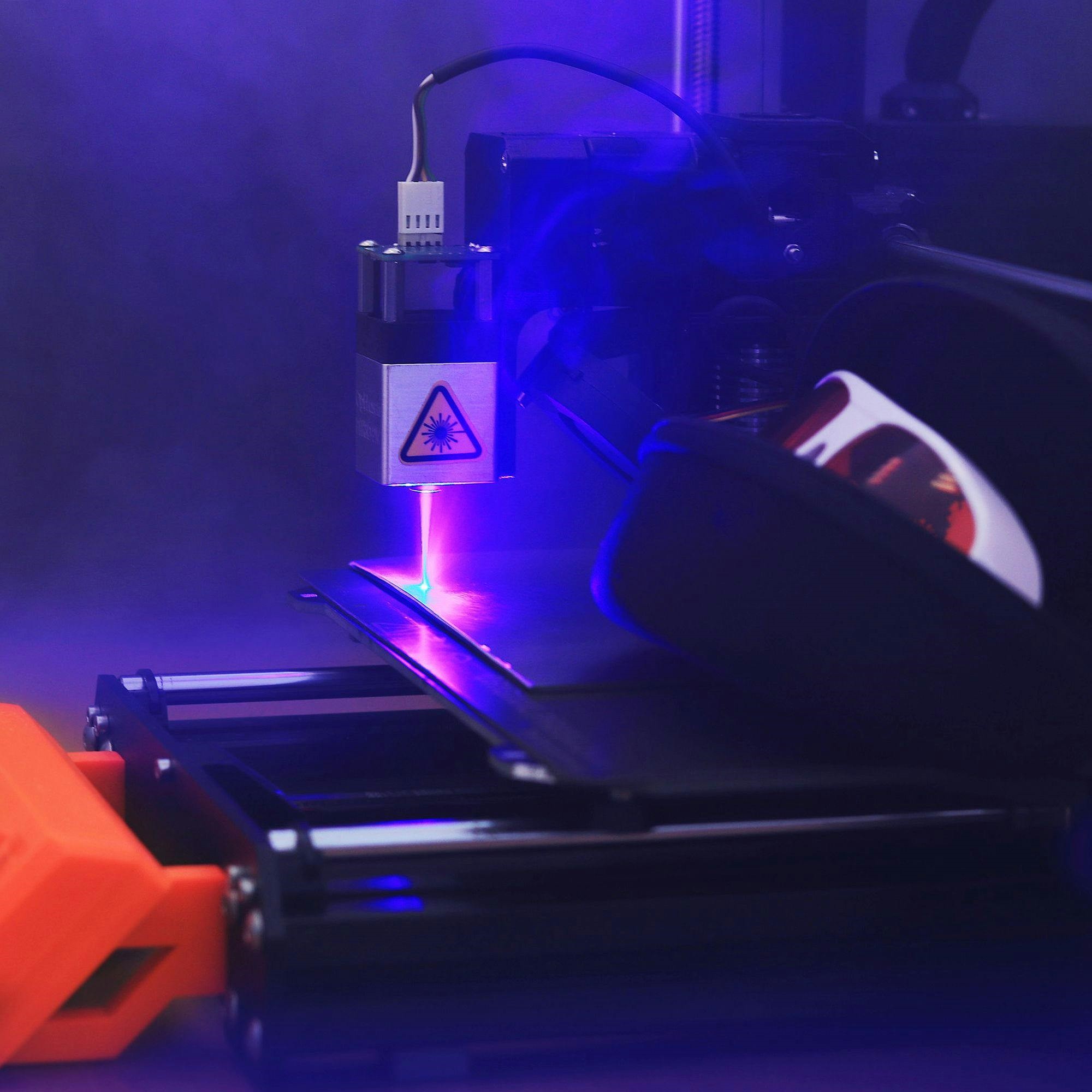

Laser cutting is a sophisticated manufacturing technique employing a concentrated laser beam guided by computer precision. The laser heats, melts, or vaporizes material along predetermined paths, allowing for intricate and precise cuts. This technology finds extensive application in diverse industries, from prototyping to intricate designs, ensuring rapid and accurate production. Its efficiency and versatility make laser cutting an indispensable tool for creating intricate patterns, precise shapes, and intricate designs across various manufacturing processes.

Laser cutting is a versatile technology capable of cutting a wide range of materials. Common materials suitable for laser cutting include:

The most significant advantage of laser cutting in manufacturing lies in its unparalleled precision. Laser cutting technology allows for extremely accurate and intricate cuts, enabling manufacturers to produce highly detailed components with minimal margin for error. This precision contributes to increased efficiency, reduced material waste, and the ability to create complex designs, making laser cutting a pivotal tool for industries where accuracy and intricate detailing are paramount.